Engineering

Our capabilities start right at the beginning with the ability to help you in the rapid development of your project.

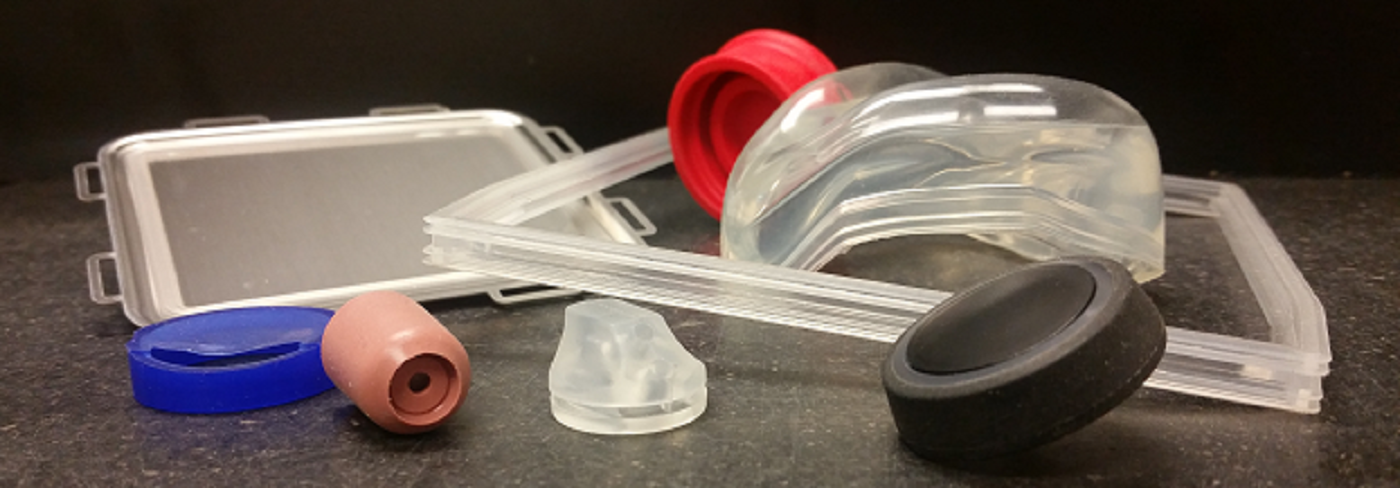

Molding Processes

Every project is different and different projects have different needs. That is why it’s important that the supplier you choose has the capability to provide you with the material and the properties that you require.

Assembly & Packaging

Along with our molding capabilities we also offer in house assembly and packaging processes. From complex medical devices to simple o-rings we can assemble and package if your needs require it.